Discover the Latest Ford Fiesta Engine Upgrades for Enhanced Power

Opening the Power of Engines: A Comprehensive Overview to Efficiency and Performance

Understanding the elaborate mechanics of engines is critical for both performance fanatics and day-to-day vehicle drivers. The responses might redefine our strategy to engine efficiency and performance in means that are both informing and crucial.

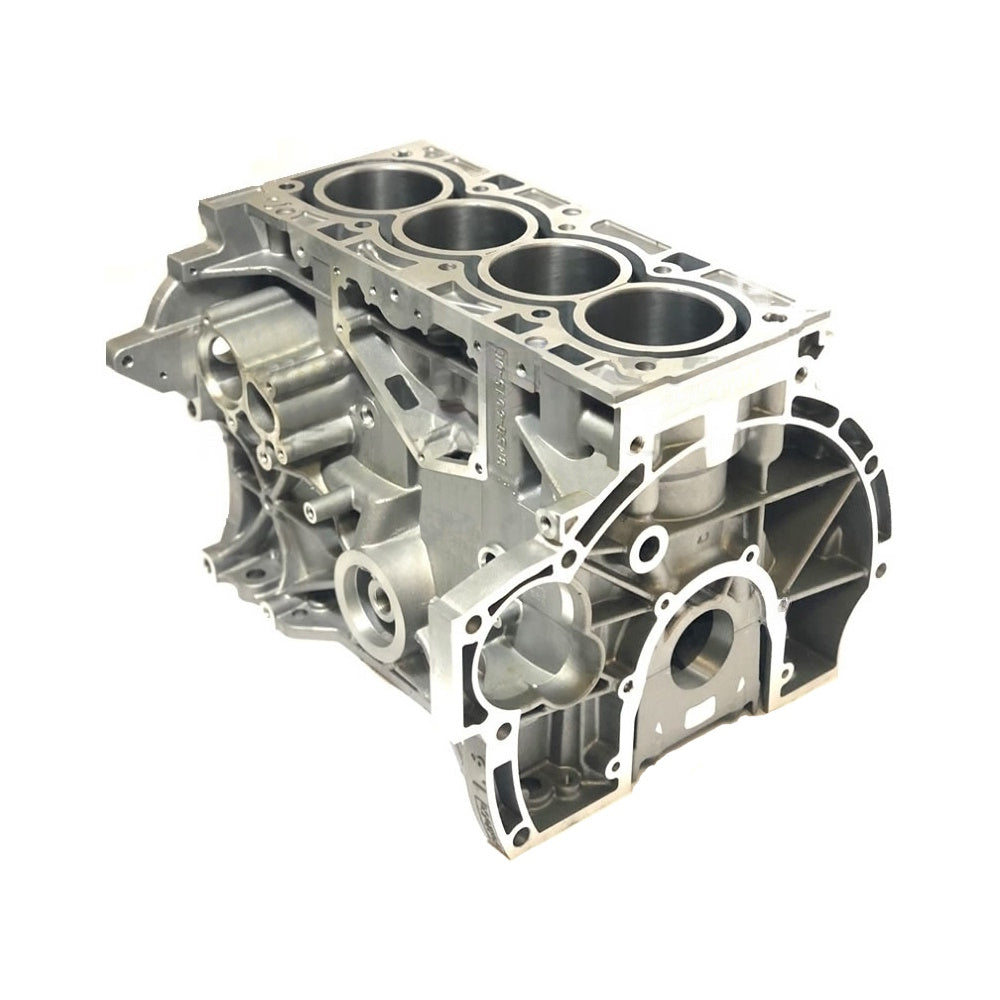

Comprehending Engine Basics

What comprises the essential mechanics of an engine? At its core, an engine is a machine made to convert gas right into mechanical power via a collection of controlled explosions or combustion procedures. The primary parts consist of the cyndrical tube, piston, crankshaft, camshaft, and valves. The cylinder acts as the chamber where burning occurs, while the piston moves within the cylinder to convert the energy from burning right into direct activity (ford fiesta engine).

The crankshaft after that changes this linear activity right into rotational energy, which inevitably powers the lorry. The camshaft regulates the opening and closing of the valves, controling the consumption of air and fuel and the expulsion of exhaust gases. Furthermore, the engine depends on a meticulously adjusted fuel-air combination, ignition system, and cooling down system to ensure optimal efficiency and effectiveness.

Recognizing engine basics additionally entails identifying the value of engine cycles, such as the four-stroke cycle, that includes consumption, compression, exhaust, and power strokes. Each phase is important in guaranteeing the engine works smoothly and efficiently. Proficiency of these basic technicians lays the foundation for exploring much more intricate engine characteristics and performance metrics, important for optimizing both power output and performance.

Trick Efficiency Metrics

Trick efficiency metrics are vital for examining an engine's efficiency and power result, giving valuable insights for both consumers and producers. These metrics function as standards for engine efficiency, permitting informed decisions in manufacturing, getting, and style.

One of the key metrics is horse power, which quantifies the engine's capability to execute work over time. Torque, gauged in pound-feet, is one more vital metric that shows the engine's rotational pressure, directly influencing acceleration and lugging ability. Gas performance, normally determined in miles per gallon (MPG) or liters per 100 kilometers (L/100km), analyzes exactly how efficiently the engine transforms gas right into activity, impacting operational prices and ecological factors to consider.

Furthermore, thermal efficiency procedures how well an engine converts fuel energy right into beneficial work, exposing understandings into energy losses largely with heat. Discharge levels, including carbon dioxide and NOx, are additionally crucial, showing the engine's environmental impact and compliance with governing criteria.

Tuning Techniques for Efficiency

Tuning strategies play a considerable duty in enhancing engine performance by maximizing performance metrics recognized in earlier conversations (ford fiesta engine). Numerous techniques exist to adjust an engine, each useful content adding to enhanced gas economic climate and decreased exhausts

One effective method is adjusting the air-fuel proportion, guaranteeing the engine operates within the optimum combustion routine. A leaner blend can enhance fuel performance, yet it should be stabilized to avoid misfires or engine knock. Furthermore, reprogramming the engine administration system can alter criteria such as ignition timing, which better enhances performance while keeping power outcome.

An additional vital approach entails modifying the consumption and exhaust systems. Updating to high-performance air filters and exhaust headers can minimize back stress, assisting in better airflow. This permits the engine to breathe more easily, bring about improved burning performance.

Furthermore, the implementation of innovative tuning devices, like dyno testing, offers exact information that enables targeted adjustments. Consistently checking these efficiency metrics ensures that adjusting initiatives produce the desired effectiveness outcomes. Collectively, these methods not only bolster engine efficiency yet additionally add to long-term sustainability in engine operations.

Maintenance for Optimal Performance

Regular engine upkeep is essential for attaining optimal performance and longevity. A well-kept engine not only runs successfully but likewise minimizes the risk of pricey repair work and break downs. Trick components calling for routine interest consist of oil, filters, belts, and trigger plugs.

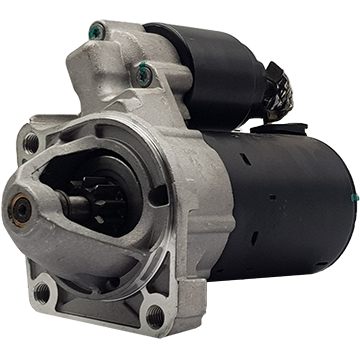

Transforming the engine oil at recommended intervals is critical, as oil lubricates relocating navigate here components and protects against getting too hot. In a similar way, replacing oil and air filters ensures that contaminants do not hinder engine function. try this site Ignoring these elements can lead to minimized efficiency and possible engine damages.

Furthermore, examining and changing used belts and tubes is crucial to avoid abrupt failings. Timing belts, particularly, should be replaced according to the maker's routine to avoid tragic engine damage.

Glow connects ought to likewise be checked and changed as required, given that they play a crucial duty in ignition and fuel performance.

Future Patterns in Engine Technology

Welcoming improvements in modern technology, the future of engine design is positioned to transform efficiency and efficiency throughout numerous applications. Among the most considerable fads is the shift towards electrification. Crossbreed and fully electrical powertrains are coming to be significantly conventional, supplying decreased emissions and improved fuel performance. This transition is not simply a pattern but a need driven by regulatory stress and consumer need for sustainable options.

Furthermore, innovations in products science are resulting in lighter, more powerful components that improve engine efficiency while reducing power usage. Advanced manufacturing methods, such as 3D printing, enable the production of complicated geometries that enhance air movement and thermal monitoring, thus optimizing burning procedures.

Furthermore, the combination of synthetic intelligence and equipment learning is set to change engine diagnostics and efficiency tuning. These innovations can examine huge amounts of data in actual time, making it possible for predictive upkeep and customized efficiency enhancements.

Conclusion

In conclusion, opening the power of engines calls for a comprehensive understanding of their auto mechanics and efficiency metrics. Carrying out efficient tuning methods and adhering to regular upkeep techniques dramatically boost engine capacities.

Furthermore, the engine depends on a thoroughly calibrated fuel-air mixture, ignition system, and cooling down system to guarantee optimal efficiency and efficiency.

Comprehending engine fundamentals also includes recognizing the value of engine cycles, such as the four-stroke cycle, which consists of intake, compression, exhaust, and power strokes. Mastery of these fundamental technicians lays the groundwork for checking out extra complex engine characteristics and performance metrics, important for maximizing both power outcome and performance.

Welcoming advancements in technology, the future of engine design is positioned to change efficiency and performance throughout various applications.